Your Project. Our People. Exceptional Results.

Maul Foster Alongi

Dedicated and Creative Consulting

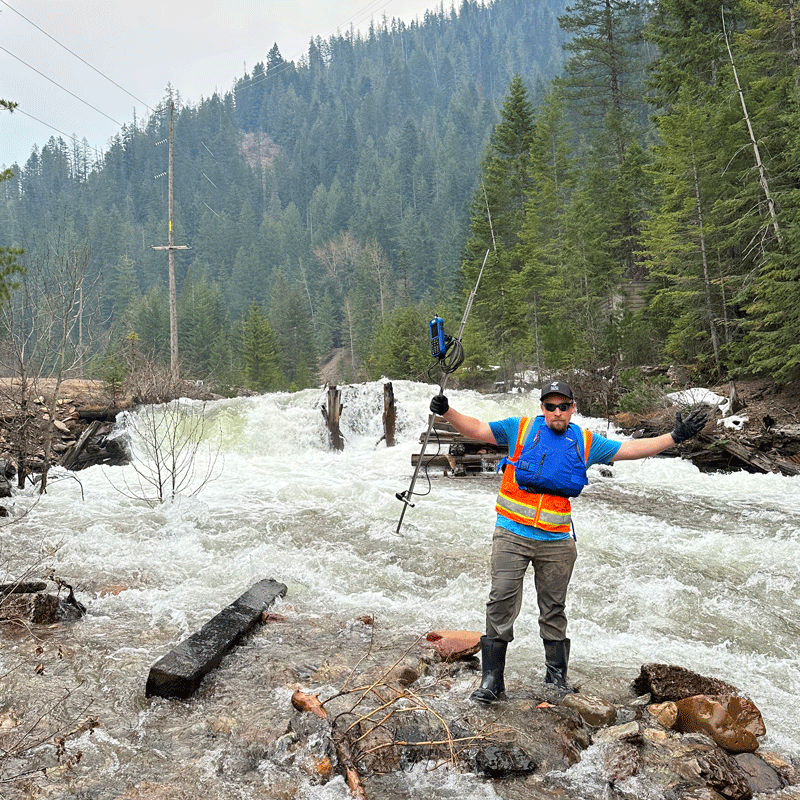

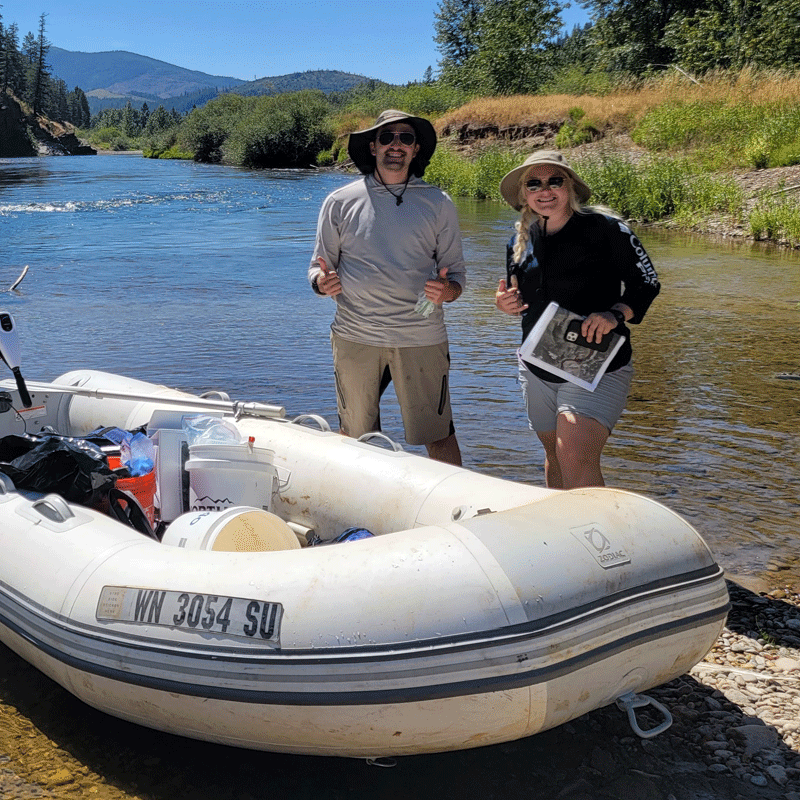

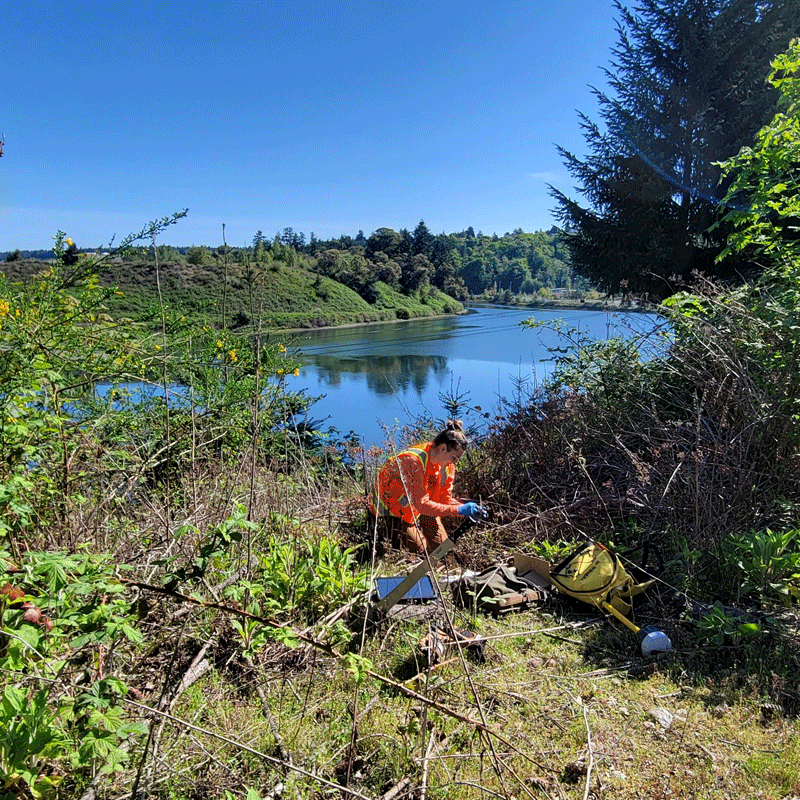

Maul Foster & Alongi is a 100% employee-owned firm providing integrated consulting services throughout the Pacific Northwest. From environmental cleanup to sustainable site development, from Phase I ESAs to GIS integrations, we blend expertise and creativity to serve our communities and improve the environment. Public sector or private sector, simple projects or complex challenges, we are dedicated advocates for your project.

Compliance Experts

We're a full-service environmental compliance science and engineering firm.

Careers

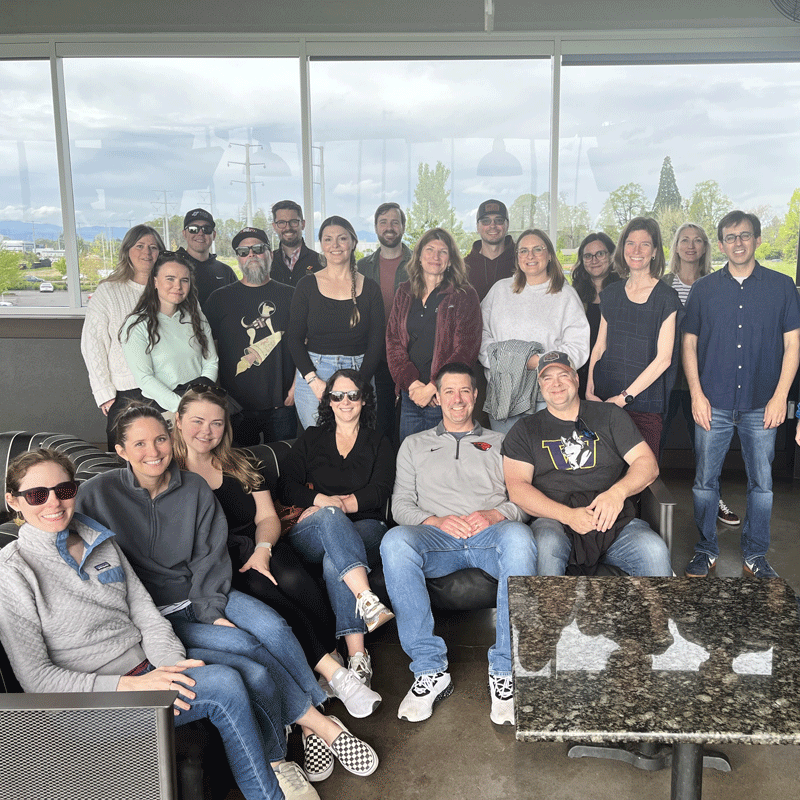

Join Our Team

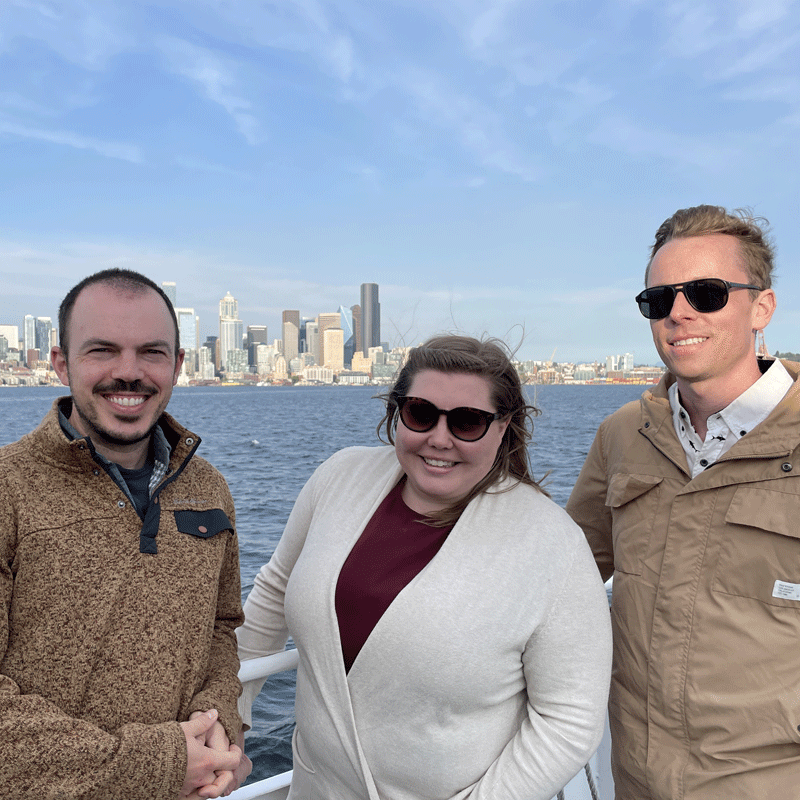

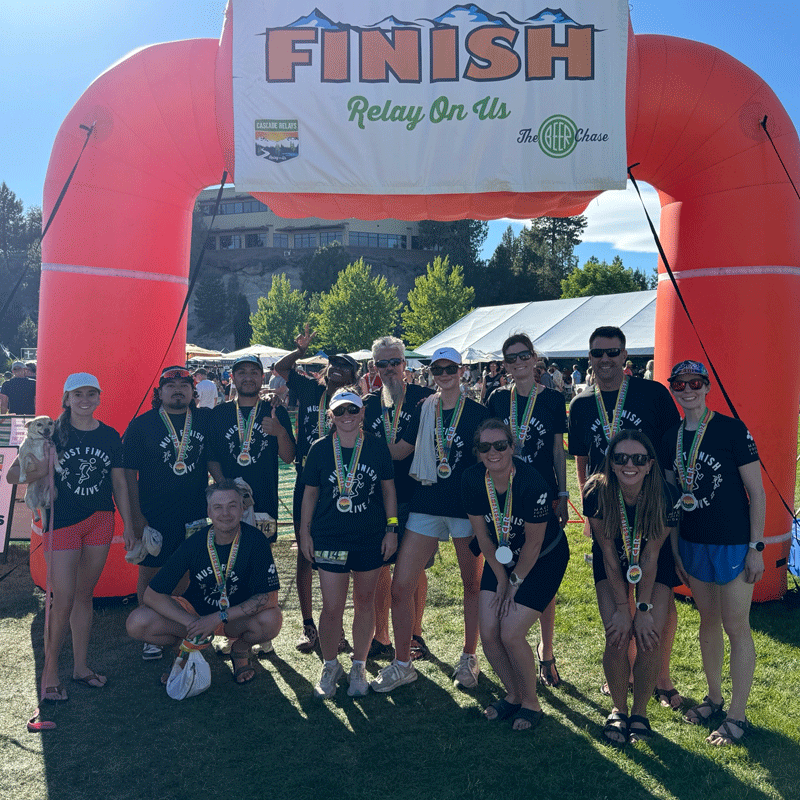

Discover a workplace where passion meets purpose. At MFA, we're about teamwork, innovation, and making a tangible difference. Does the idea of collaborating across disciplines to solve complex problems in a 100% employee-owned company sound like fun? Then we want to hear from you.